World-leading supplier of handling equipment to the rolling mill industry

We supply handling systems for wire and rod mills, as well as strapping and marking solutions for strip mills. Our equipment is a crucial part of rolling mills all around the world and our wide range of solutions can be found in plants of all types and sizes.

Solutions for wire, rod and strip mills

Once the wire, rod or sheet has been rolled into its final shape, our equipment ensures that it is prepared for delivery according to the specifications of the end customer. Our handling systems include functions such as collecting, sorting, packaging, weighing, marking and unloading.

Wire

Our wire handling system can handle wires of all types, including bar-in-coil.

Bar & section

Our bar handling system can handle every type of bar, hollow profile and heavy section.

Strip coil

We offer strapping and marking solutions for both hot and cold applications.

About us

We increase your productivity

Utilize market-leading performance, durability, energy efficiency and safety to increase productivity and reduce costs.

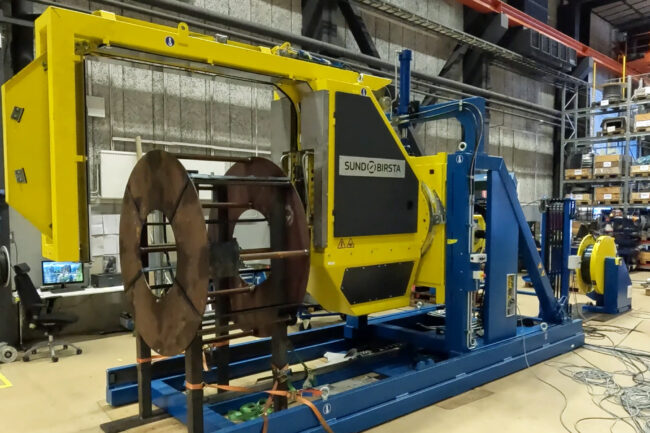

Sund Birsta – the industry standard

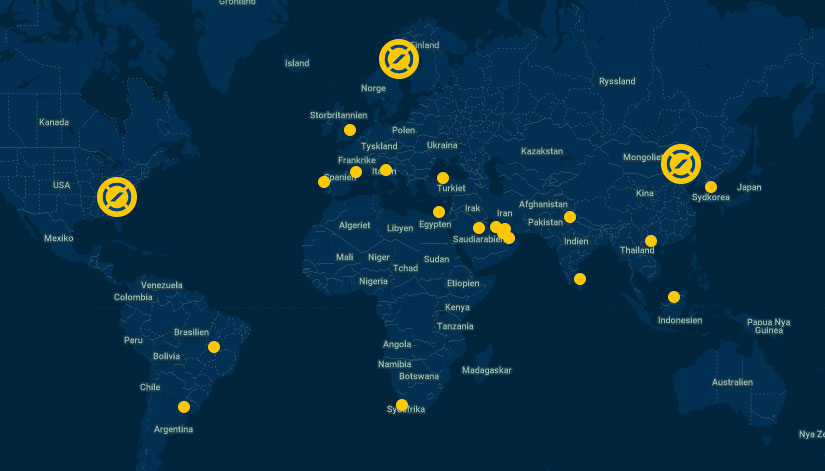

Ever since the first Sund Birsta machine was commissioned in the 1960s we have been setting new standards for performance, durability, energy efficiency and safety. Today, we are considered the leading supplier of handling equipment in the rolling mill industry. We have delivered thousands of solutions to satisfied customers all around the world – such as China Baowu Group, ArcelorMittal, Posco, Nippon Steel, Nucor, Thyssenkrupp, TATA Steel, Jindal Steel & Power, JSW Steel, Hoa Phat and Liberty Steel, Emirates steel, Saudi Basic Industries among others.

An investment in increased profitability

By choosing a solution from Sund Birsta, you can minimize unplanned production stops, production waste and customer complaints due to handling errors. This enables you to increase your profitability.

Sund Birsta – a part of Danieli

Sund Birsta has long been part of Danieli – one of the world’s largest suppliers of plant equipment in the metal industry. Danieli has a global presence with offices and personnel all over the world, which gives us resources to better serve our customers – no matter where they are. Being part of Danieli also gives us a deeper understanding of the entire process, from production of the raw material to rolling of the finished product.

Latest news

Stay informed

Stay informed with the lastest news from Sund Birsta.

Our offer

Together we can improve your profitability

Let us help you improve your profitability with our innovative solutions. By choosing a solution from Sund Birsta you will utilize market-leading performance, durability, energy efficiency and safety to increase productivity and reduce costs.

60+ years of experience

We have been supplying handling equipment to satisfied customers in the rolling mill industry for over 60 years and our solutions are suitable for plants of all sizes and types. To ensure maximum return on your investment, we also offer a complete range of aftermarket products and services.

Standard or custom solutions that suits you

Sund Birsta offers both standard and custom solutions based on your unique needs. Let us use our wide range of products and services, our extensive industry experience and our renowned innovative ability to find a solution that suits you.

Our products

A wide range of solutions

We have a wide range of solutions for handling all types of products – from durable infrastructure steel to exclusive materials and surface-treated products that must be handled with great care.

Wire

Coil handling

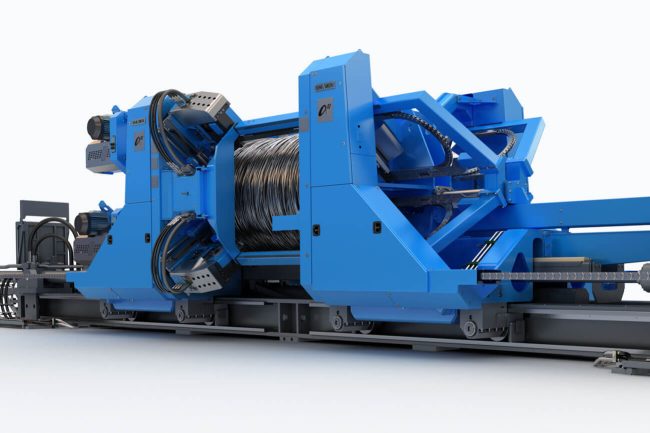

The handling system is capable of transporting, tilting, elevating and rotating the wire coils in both vertical and horizontal position. The system is modularized and can be easily adapted to fit the desired layout, capacity, coil weight and buffer demand.

Products

Strapping Spooler Coil

Products

Distribution

The wire distributor makes sure that the ring laps are optimally distributed into a coil.

Products

Collection

The coil collector enables precisely controlled collecting of the distributed ring laps onto a vertical pallet.

Products

Compacting

The handling system includes one or several vertical and horizontal compacting stations. Our state-of-the-art compactors can be adapted for a wide variety of applications (including off-line) and equipped with wire binding and strapping systems.

Products

Tag Marking

The marking station enables efficient marking of the wire coils and can be adapted for a wide variety of customer demands.

Products

Unloading

The unloading station is designed as an intermediate storage and can be adapted for specific customer demands.

Products

Bar & section

Bar Handling System

The handling system includes chain conveyors, roller tables and transfers – capable of transporting the bars and bundles between stations. The system is modularized and can be easily adapted to fit the desired product, layout, capacity, and buffer demand.

Products

Separation system

Products

Short bar ejection

The short bar sorting enables detection and removal of short bars.

Products

Counting

The handling system includes one or several bar counters depending in the desired layout. Our state-of-the-art bar counter offers the best bar counting accuracy on the market and handles Ø8-65mm bars.

Products

Collecting

The system includes a bundle collecting station that can be adapted for collecting sub and master bundles.

Products

Forming

The handling system includes bundle formers for wire binding applications and roller conveyors for strapping applications, which shape the bundle prior to wire binding or strapping.

Products

Bending

The handling system offers solutions for sub and master bundle bending, enabling efficient transportation.

Products

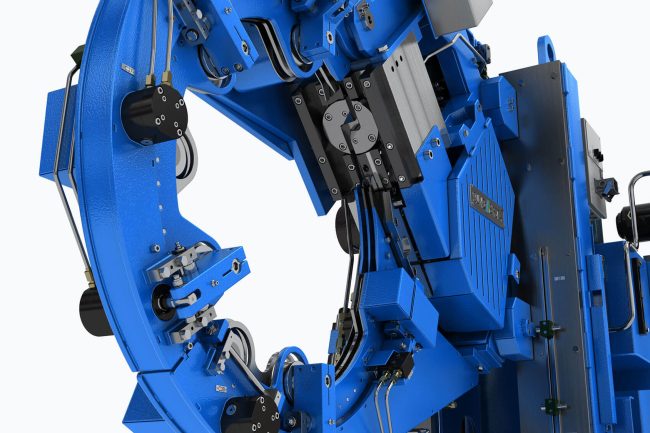

Strapping(also for heavy sections)

The handling system includes one or several strapping machines depending in the desired layout. Our strapping machines offers the highest sealing strengths and shortest cycle times on the market.

Products

Binding(also for heavy sections)

The handling system includes one or several binding machines depending in the desired layout. Our renowned wire binding machines offers the best performance on the market and can be adapted for a variety of sub and master bundling applications.

Products

Weighing

Marking

The tag marking station offer automatic marking of the bundles according to your specific needs.

Products

Strip coil

Accessories

Strapping

Our strip coil strapping machines are used in a wide variety of circumferential and through-the-eye strapping applications. Our track record includes successful strapping of strip coils immediately after winding, which is one of the toughest applications in the industry.

Our services

We got you covered

We offer a complete range of aftermarket products and services.

Helpdesk and support

We offer our customers the opportunity to contact our helpdesk if you encounter problems. The Sund Birsta helpdesk aims to deliver an exceptional level of service to our customers. We have qualified technicians that will answer most of the questions directly and if needed set you in contact with the right person for your case.

Contact supportAftermarket service

By choosing aftermarket products and services from Sund Birsta you maximize the return of your investment. We offer spare parts, upgrade programs and service on site or send us the machine that needs service to our workshop. Our workshop service includes everything from inspections to full machine rebuilds. Contact us and we will find a solution for you to get the best service.

Digital service tools

With the Sund Birsta Internet of Things (IoT) solution, our specialists can perform online diagnostics and troubleshooting of your equipment. It also enables continuous collection of production data, which makes it possible to improve preventive maintenance and optimization. Furthermore, we can make customized offers for products and services based on your unique application.

Sund Connect™Email: info.egypt@sundbirsta.com

Email: info.southafrica@sundbirsta.com

Email: info.indonesia@sundbirsta.com

Email: info.korea@sundbirsta.com

Email: info.vietnam@sundbirsta.com

Email: info.uk@sundbirsta.com

Email: info.italy@sundbirsta.com

Email: info.spain@sundbirsta.com

Email: info.turkey@sundbirsta.com

Email: info.uae@sundbirsta.com

Email: info.argentina@sundbirsta.com

Email: info.brazil@sundbirsta.com

Email: info.germany@sundbirsta.com

Email: info.mexico@sundbirsta.com

Email: info.qatar@sundbirsta.com

Contact

Get in touch with us

We have offices in Sweden, USA, China and India as well as a global network of sales representatives.

Sweden

Sund Birsta AB

Heffners allé 51

856 33 Sundsvall

SWEDEN

Phone: +46 60 13 94 00

E-mail: info@sundbirsta.com

USA

Sund Birsta Inc.

115 Industrial Loop N, Unit A

Orange Park, FL-32073

USA

Phone: +1 904 930 2284

E-mail: info.usa@sundbirsta.com

China

Sund Birsta Metallurgical Equipment Co., Ltd

Rm.825, N Block, Guangyao Dongfang Plaza, No.18, Yangfangdian Road, Haidian District, Beijing, P. R. China

Phone: +86 10 6815 9550

E-mail: info@sundbirstame.cn

India

SundBirsta India Pvt Ltd

Office No. 301-C, Delta-1, Giga Space Condominium, Viman Nagar

Pune-411 014, Maharashtra

India

Phone: +91 72077 33110

E-mail: info.india@sundbirsta.com

Agents

Below you can find contact information to our sales representatives.