Wire

Compactor

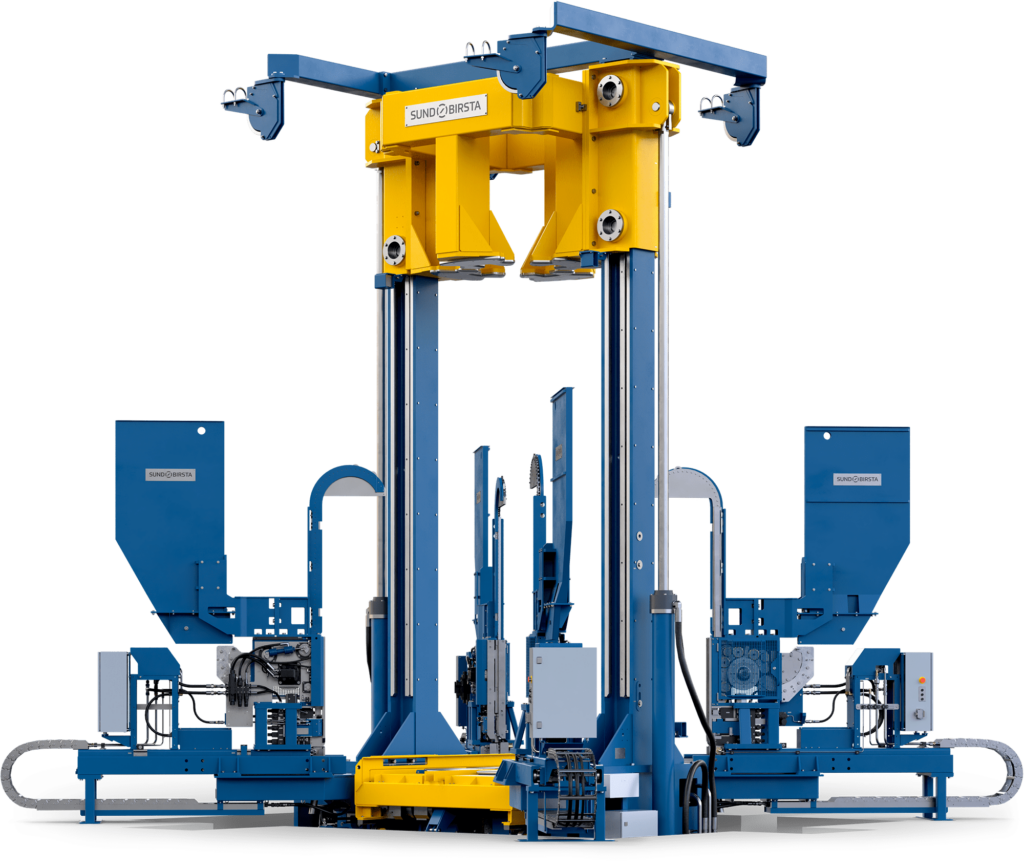

PCVA

The PCVA Compactor is designed to efficiently compact wire rod coils in rolling mills. It can be adapted for a variety of applications and equipped with wire binding or strapping systems.

Efficient vertical compacting

Building on proven Sund Birsta technology, the PCVA is an accurate, reliable and low-maintenance vertical compactor.

High availability

The high availability of the compactor increases productivity and reduces costs.

Proven technology

Building on proven Sund Birsta technology, the PCVA is a reliable compactor in plants all around the world.

Long life span

The robust design and construction of the PCVA makes the machine reliabe and durable.

Small footprint

The vertical design of the PCVA makes it ideal for plants where floor space is scarce.

Easy access to service

Protection covers are easy to dismount, giving good access to maintenance of the machine.

Variable pressure

The pressure of the PCVA Compactor can be adjusted steplessly between 100 and 400 kN.

Operations of PCVA Compactor

The PCVA Compactor is designed to compact wire rod coils with a pressure of 100–400 kN. It consists of a movable press plate, a roller conveyor, and four units for wire binding or strapping.

High availability and easy access for maintenance are features making the PCVA a cost-effective investment.

Advanced Human-Machine Interface (HMI)

The human-machine interface of the PCVA features operational information as well as information on preventive maintenance and fault finding.

Internet of Things (IoT)

With the PCVA, you have access to powerful analytics from anywhere, thanks to our comprehensive built-in IoT solution.

Wire binding

The KNB binding head makes a strong, parallell twisted knot with no protruding ends. It has a well-proven design, known for its reliable performance.

Strapping

The SBHX5 strapping unit punches five pairs of seals: four lock seals and one security seal. The SBHX5 is a high quality unit with long life-span, designed for easy access to maintenance.

High availability

The high availability of the compactor increases productivity and reduces costs.

| Technical specification | PCVA |

|---|---|

| Height (mm) | 7500–7900 |

| Width/depth (mm) | 5900–6600 |

| Binding wire (mm) | 6.3–7.3 |

| Binding strap (mm) | 0.8 / 1.0 x 32 |

| Max. coil weight (kg) | 4000 |

| Min./max. pallet height (mm) | 3200–4700 |

| Min. cycle time (s) | 44* |

| Net weight (kg) | 29300–33500 |