Slit Coil

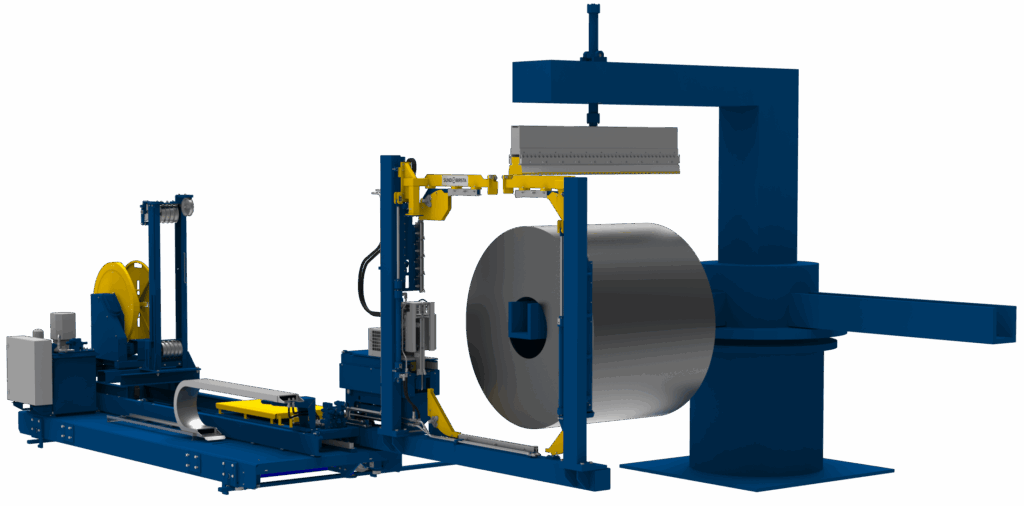

Strapping Machine

This strapping machine applies circumferential straps to slitted coils. The machine is moveable in and out of the line to allow the unloading car to pass through to the turnstile, and moveable sideways to allow strapping on any position of the coil.

Reliable strapping for slitted coils

Customizable to your requirements – delivering efficient and reliable strapping.

Customizable

The machine can be customized to your specific needs in terms of coil diameter, slit widths, snubber arm design and other existing equipment.

Advanced sealing technology

Equip the machine with the strapping head of your choice. Sund Birsta offers a wide selection of strapping heads capable of creating sealless mechanical joints.

Quick exchanged strapping heads

The machine can be equipped with strapping heads for both 19 mm and 32 mm strap, and it is possible to switch between the pair depending on your production needs.

Support

Our dedicated Customer Service team ensures you receive the support you need, when you need it. Your production is our priority.

Remote service

The machine is compatible with our IoT solution, enabling quick and solution-oriented remote support from Sund Birsta’s experienced engineers.

Safety solutions

Sund Birsta provides customized safety

solutions that comply with applicable standards and meet your specific requirements.

Operation

When the coil is delivered to the Turnstile, the machine is in its retracted home position. When the Unloading Car releases the coil and returns to its home position, the machine moves forward into the production line. Strap is pre-fed through the strap guide system and the machine moves sideways to the first strapping position. The strap guide system connects with the Snubber Arm and the strap is fully fed through the system and into the Strapping Unit. The strap is then clamped, and the Feeding Unit retracts surplus strap while the Strapping Unit moves towards the Coil. The Strapping Unit performs the seal, cuts the strap and returns to its retracted initial position. The strap guides remain connected to the Snubber Arm and the machine moves sideways to the next strapping position. The cycle repeats until every slit has been strapped, then the machine moves back sideways to release the coil and allow the Turnstile to convey the coil. The machine retracts to its home position to allow the Unloading Car to deliver the next coil to the Turnstile. And so, the cycle repeats.

Strapping Machine

Features

Accurate application of straps

Connecting the strap guide system with the turnstile snubber arm enables accurate strapping.

19 or 32 mm strap

It is up to you – still the brilliant result of Sund Birsta’s sealing technology.

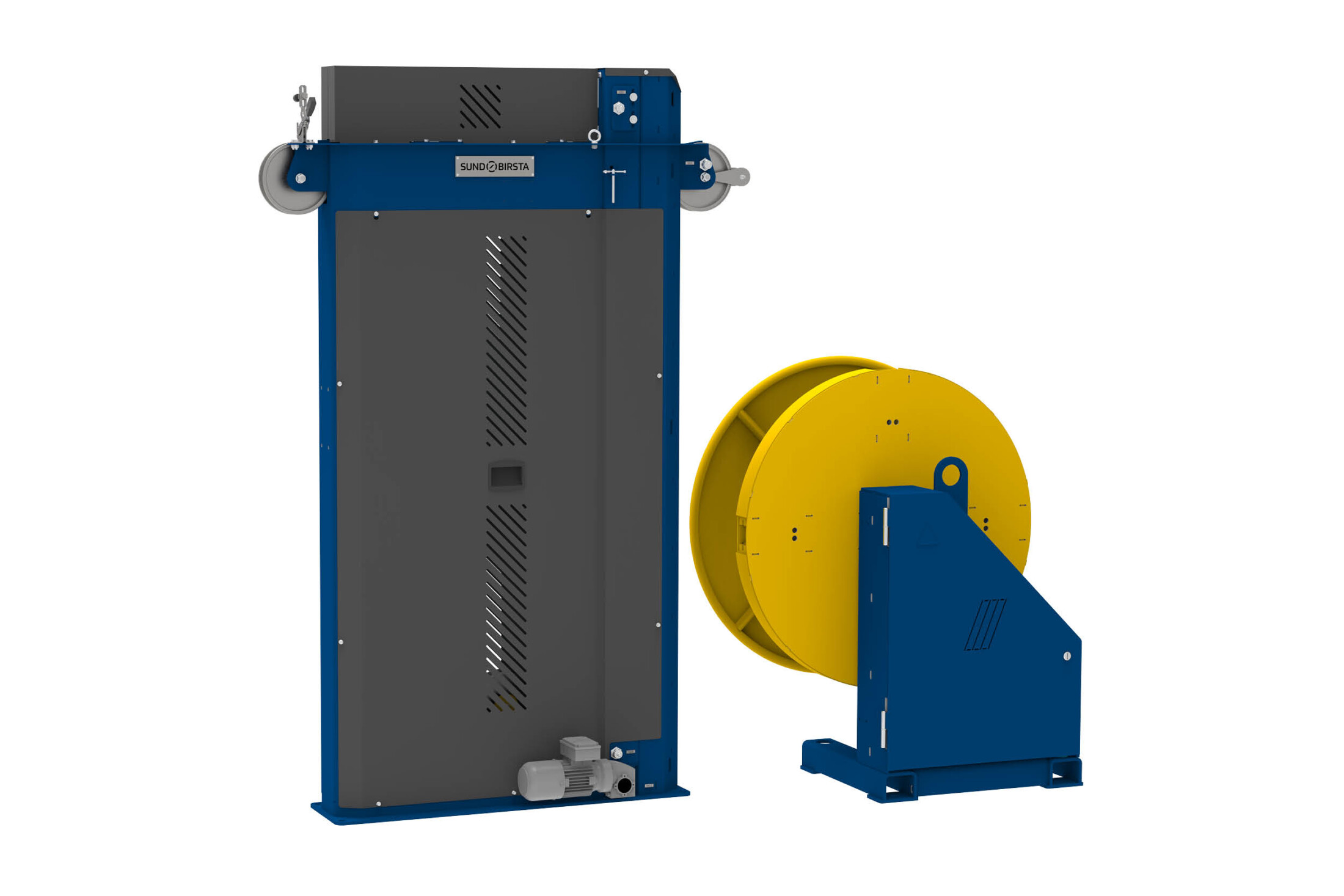

Next generation Accumulator

Faster, safer and more ergonomic. Discover our new accumulator.

Click here to read more

| Technical Specification | |

|---|---|

| Sealing technology | Mechanical |

| Strap width | 19-32 mm |

| Coil sizes | Customizable |

| Slit widths | Customizable |

| IoT compatible | Yes |

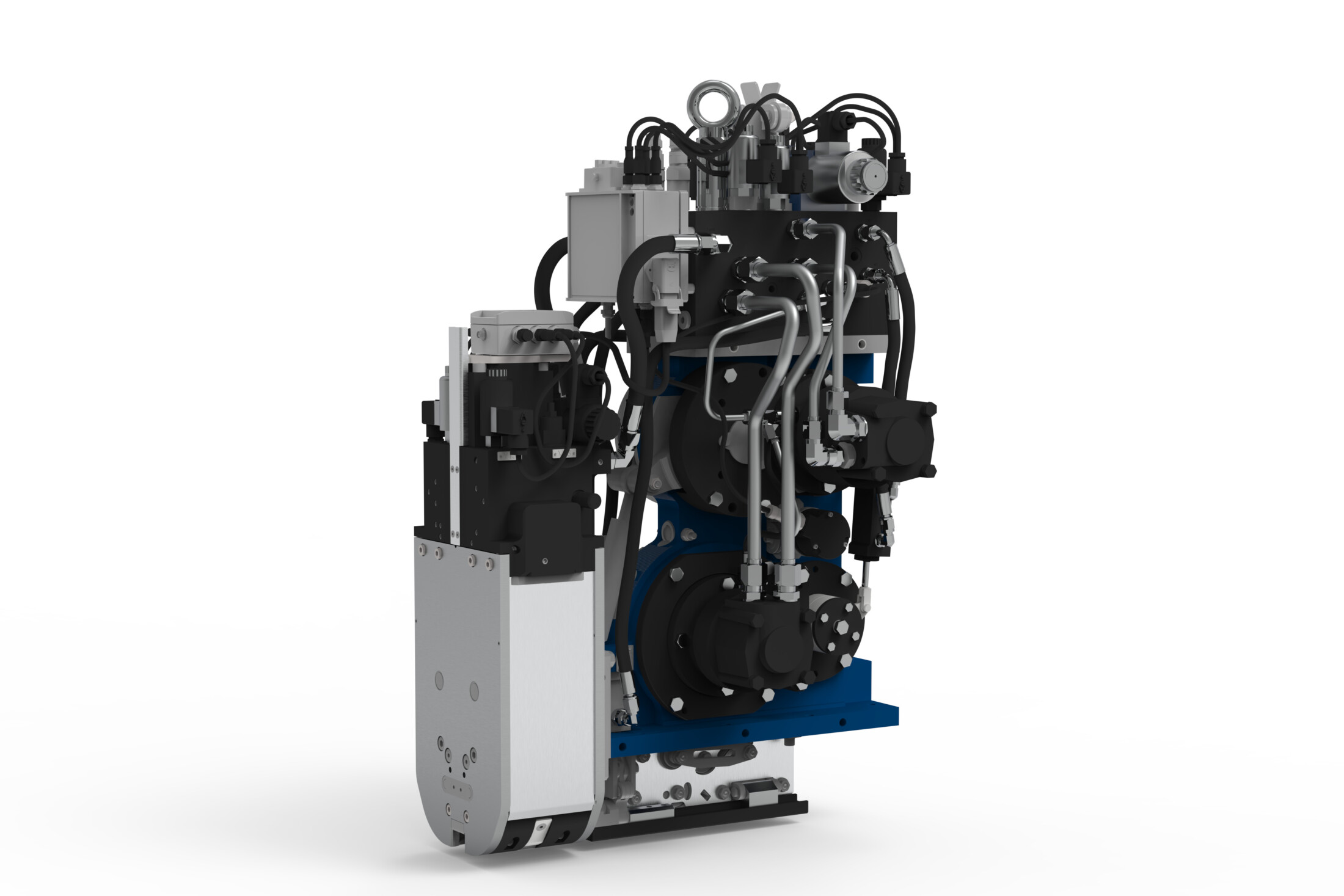

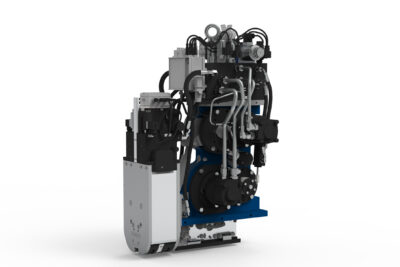

SBHX5

- Sealless mechanical joint

- For 32 mm steel straps

- Retains 80% of the steel strap’s tensile strength

- Wear parts have a lifespan of up to 80,000 cycles

SBHXS3

- Sealless mechanical joint

- For 19 mm steel straps

- Can be retrofitted

Our strapping heads can easily be fitted into existing strapping machines.